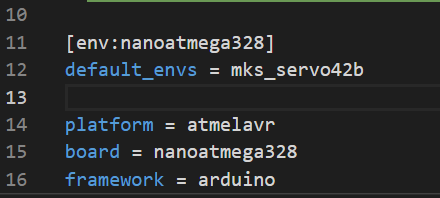

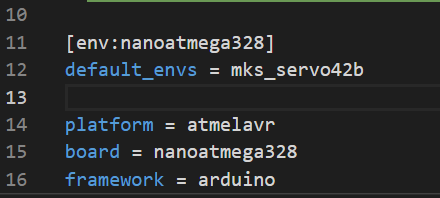

trying to work with the MKS stepper. Git hub said to add " default_envs = mks_servo42b" to the Platformio.ini . Have I done this correctly? What does this accomplish?

Yes I’m new and don’t have a clue!

Greg

trying to work with the MKS stepper. Git hub said to add " default_envs = mks_servo42b" to the Platformio.ini . Have I done this correctly? What does this accomplish?

Yes I’m new and don’t have a clue!

Greg

A default_envs directive only makes sense if you have a platformio.ini with multiple environments (e.g, [env:uno] and [env:nanoatmega328]) and you want to select which is the default environment that will be used for IntelliSense and building and uploading etc.

Per docs, this is only allowed in the [platformio] section. You’re putting it inside some other environment, referencing an environment that doesn’t exist according to what I can see in the screenshot. So, this doesn’t make much sense.

What exactly do you want to do? Create your own firmware and use a library so that you can interface with this stepper motor? Or do you just want to compile the existing project GitHub - makerbase-mks/MKS-SERVO42B: MKS SERVO42B is 3d printer closed loop stepper motor NEMA17 MKS SERVO42 developed by Makerbase that prevents losing steps. CPU is STM32F103C8T6 ARM 32-bit Cortex™-M3 CPU Core,72 MHz. Magnetic encoder is Allegro's A1333LLETR-T Contactless 0° to 360° angle sensor IC ,12bit .This Project open source hardware and code,support platformio build and upload firmware...?

Thanks for the reply, I am only using the Platformio program? Coming from Arduino and having watched the intro to Platformio on Dronebotworkshop I thought this was the way to go and everyone says that C++ is much better. Having said that I can see the advantages to both but still trying to tell if a issue is C++ or related to Platformio not set up correctly by me.

What I’m trying to do is using Nano, with ACS712 sensors, to drive a close loop stepper to specified position for each sensor. This is for a dust collection system for my wood working tools. When a tool is used the associated sensor tru an Analog port would tell the stepper to go to a position ie. 45, 90,135 etc. 8 position in all. 8 sensor, 1 per tool. Each position lines up a opening “blast Gate” for that particular tool and creates a path way for the vacuum system to pull away the saw dust.

If you need more information would be happy to supply.

Thanks

Greg

I"m new to this group so there is a lot I don’t understand. I thought I might get a reply after my reply to you. Maybe I’m beyond help?